GENESIS INFINITY

We produce high quality, cost-effective stretch films available in the machine and hand-applied formats that save you time, money, and primary packaging damaged goods.

DRIVING INNOVATION WITH NANOTECHNOLOGY

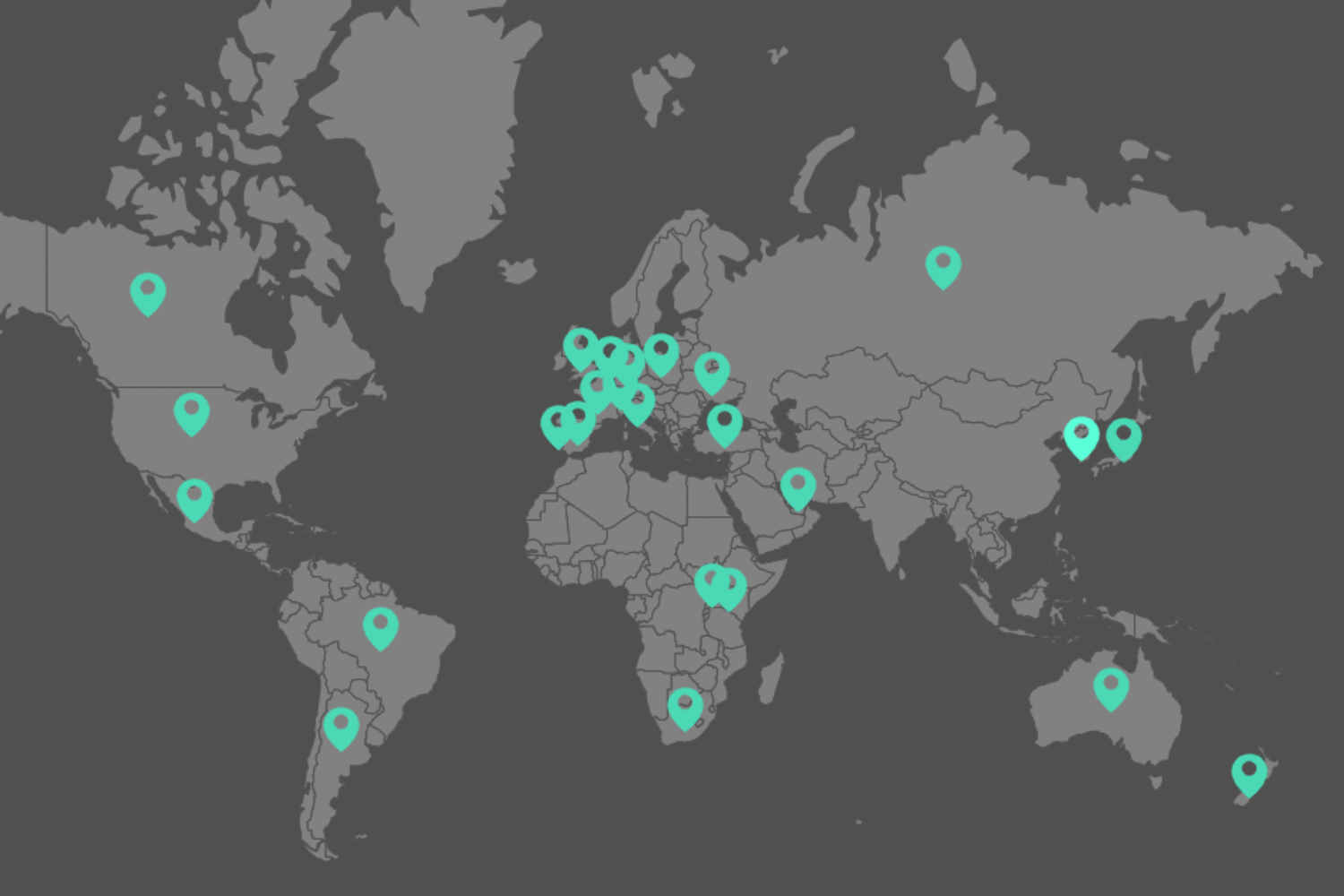

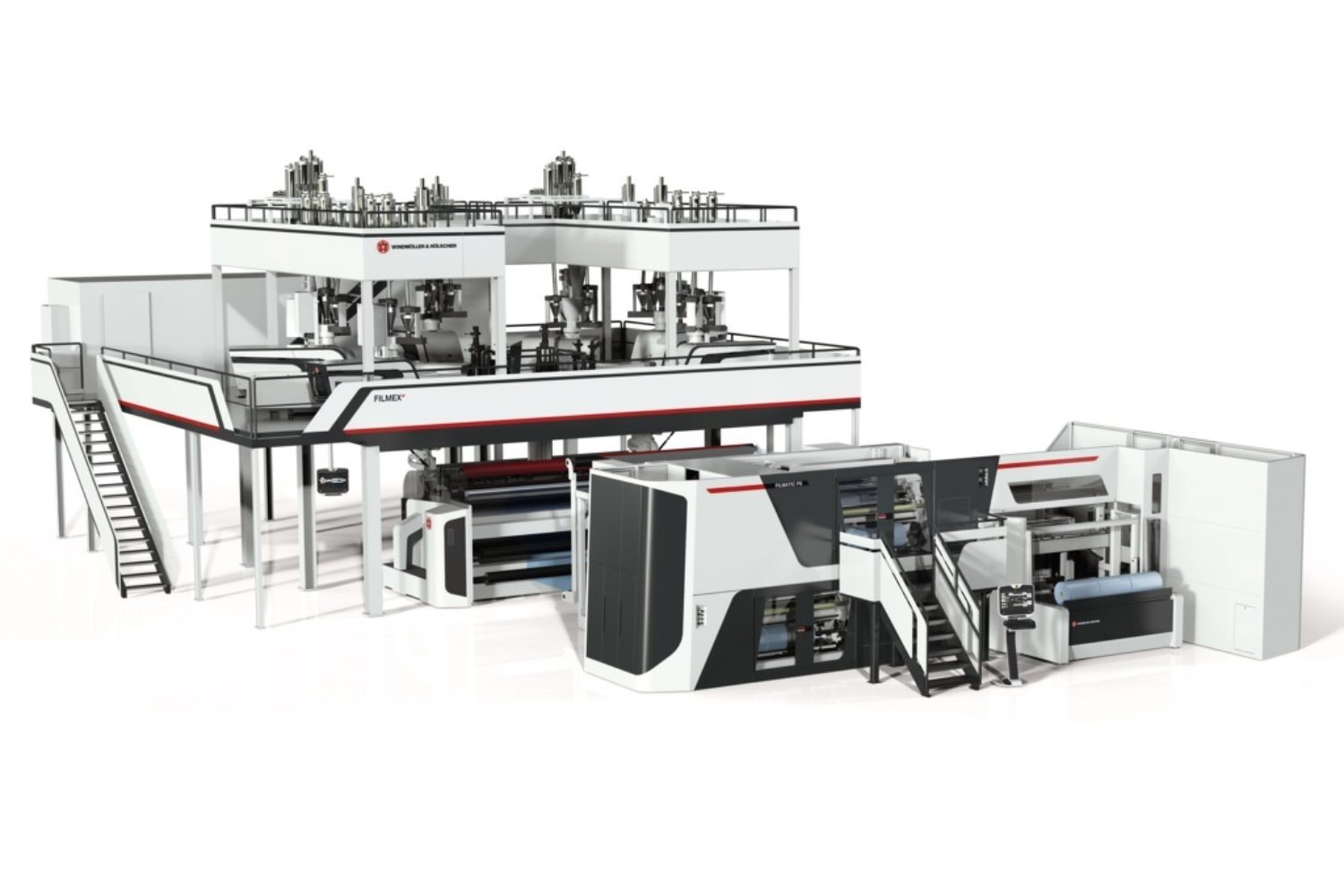

Superior films add value to your business by protecting your valuable products from shipment to the doorsteps of your client. As such, our 55 layers “thin” stretch films guarantee lower consumption and stabilisation of load over time. We continually develop innovative solutions that add value to your investment. We are one of the 1st in the World to install the nanotechnology cast line, which is capable of producing 55 layers of stretch film.

Super “thin” gauge film, superior performance. Our nanotechnology cast line can produce super “thin” gauge film that offers excellent function. Each nanolayer is designed and stacked strategically to achieve super thin yet resilient performance. The super “thin” stretch film brings excellent puncture and tearing resistance.

No more compromised pallets, reduce unsaleable goods. With Genesis Infinity, you can achieve an optimum containment force to keep your shipment safe. Its holding strength can sustain punctures, where any perforation on the film will not lead to further tearing. Thus, significantly reduce your unsaleable goods, returned by your customers due to damages during transit. Besides, your per load packaging cost can also be reduced significantly without the need for more film due to its toughness.

Reduce usage per wrap and high sustainability. Our nano gauge film can be stretched up to 400%, meaning turning one meter into five meters. Along with its toughness, you can significantly reduce the raw materials required per wrap. On a typical high-speed wrapping machine, a conventional stretch film has a high possibility of snapping, which translate to more wastage. Our 55-layer nano stretch film helps you achieve greater sustainability on a high-speed wrapping machine.

THE INCREDIBLE LOAD SOLUTION

WHY?

- Absolute perfect match for most of the arm wrapper and turn-table wrapper

- Achieve the highest holding force with thinner gauge

- High tear resistance to avoid film breakage at sharp corner

Practically, there are many variables in wrapper design, sensor sensitiveness, pre-stretch roller surface, film speed and etc. To overcome this problem, Genesis Infinity is designed to adapt most of the variables but not scarify the load stability and safety.

HOW?

Majority wrappers in the market able to stretch from 150% – 200%

Cost saving with high holding force

- Cost saving and high holding force

- Quality is consistent and high traceability

- High tear resistance